Our Trip to Brobdingnag

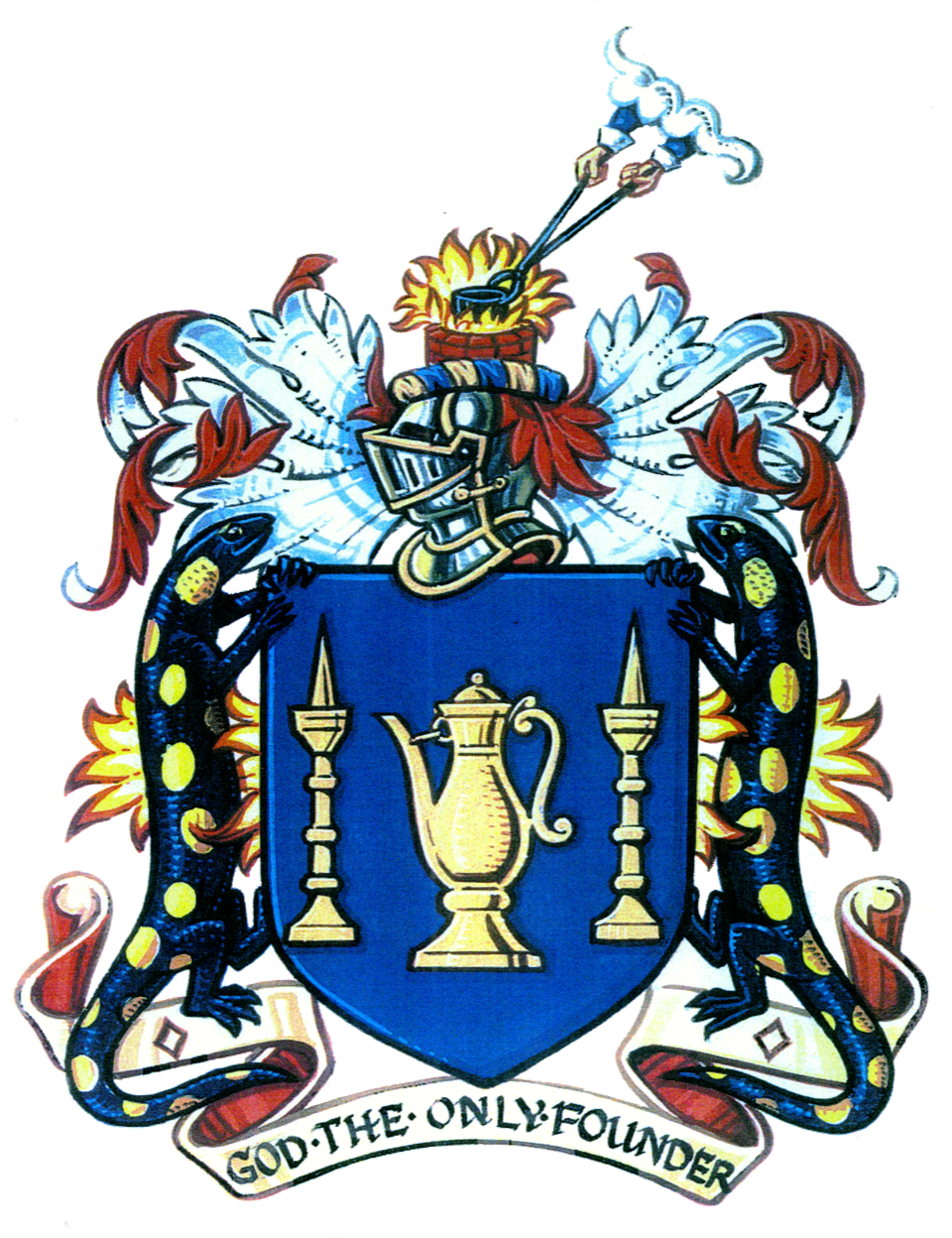

Members of the Founders’ Company during their tour of Sheffield Forgemasters

Members of the Industry Committee, our Assistant Clerk, Liverymen and Freemen were recently honoured with a tour of Sheffield Forgemasters, the MOD-owned foundry and forging company that offers sovereign capability in the UK for the manufacture of complex engineered components.

The company, which covers a large and growing acreage in Sheffield, comprises steelmaking (to nuclear grade quality), forging, sand casting (using secondary – aka scrap – steel as the raw material for ingot or component manufacture) and machining of large and ultra large components, as well as heat treatment ovens, quench tanks and testing & inspection kit, supported by an in-house research & development capability, offering a vertically integrated facility that is unrivalled in either the US or Australia.

With 670 staff, of whom 100 are graduates and 15 have PhDs, the company also continues to invest in its future talent with 61 apprentices across the various departments, some of whom are also currently studying for the Diploma in Casting with the Institute of Cast Metals Engineers.

Our visit was kindly hosted by Group Technical Director, Ian Nicholls FICME, who was extremely generous with his time, providing us with a presentation covering the history of the company, its technical capabilities and also the current plans for recapitalisation and investment aimed at ensure that the UK is able has access to the vital component production capabilities needed for the manufacture of defence submarines, ships and oil and gas, as well as containment parts for explosives testing. He then walked us around the many departments across the site, including a stop for lunch in the on-site restaurant.

The foundry is capable of producing castings with a 600t poured weight, 350t finished weight, which is almost unique in Europe and the forge contains a 10,000t press mainly used for defence work and a 4000t press for commercial orders, capable of forging ingots up to 285t in weight, up to 5m in diameter as discs or hollow parts, and a maximum of 20m in length.

Future Proofing our UK Capabilities

Ian explained that a major programme of recapitalisation was underway, with an investment of £1.3 billion committed for the improvement of the facilities to be able to supply critical defence assets for the UK, the MOD having acquired the company in 2021 to enable this. Land nearby, some 20 acres, has since been bought, plans finalised and building work is now well underway to build a new 12,800m2 building to house a new 13000t hydraulic forging press and related process plant. With machining capacity being one of the key bottlenecks for production, a new machine shop is being built, having a completion date of 2027, and flood resilience (prevention) incorporated across the site, as well as upgrades to both the melt shop and foundry.

Key to the plan are high voltage power upgrades to supply the new facilities with the electricity needed, as well as improved cyber security due to daily threats, and the implementation of enhanced digital technologies - and of course the planning team also have to consider the logistics of moving such enormous components both around the site as well as onto and off-site to customers, so plans include a 220T rail bound forging manipulator.

Viewing the newly purchased automated robotic additive foundry pattern manufacturing facility.

With the company’s focus moving towards increased flexibility and greater agility to meet defence requirements, much smaller (relatively speaking) parts are now being produced in addition to the huge components the company is historically known for, and we were able to view the new robotic additive printing kit that will be used to print patterns for these smaller castings, reducing the reliance on traditional wooden patterns that require huge hand skills and much time to produce. This will integrate pattern production with the simulation and modelling tools that are now ubiquitous to the design and production of castings in the UK.

Ian explained how the new investments will support the company deliver the UK’s requirements for high integrity components, in some cases with zero weld repair, zero defect quality criteria.

“Everything is just huge,” said Pam, Industry Committee Chair, “- the furnaces, the moulding pits, the cranes, the ovens. I think some of our Founders’, who perhaps had not previously visited a forge, or indeed a foundry, and even those who had been to many, were just astounded by the scale of everything. And at the same time, it was great to see the amount of high value work in progress across the enormous site. Those who have travelled past Sheffield on the M1 will have seen the two large Forgemasters buildings that dominate the city skyline, but will have had no idea about the other buildings. The new investment that is underway, and the size of the ambition, is really pleasing to see for those of us who want to see continued support and growth in UK manufacturing.”

Master Alan Hughes agreed, saying, “Do please pass on our thanks to Ian and his colleagues for giving up so much of their valuable time and for making us so very welcome.

“The whole tour was fascinating and a complete eye opener. The sheer scale of the place was breathtaking. As a founder, albeit on a very different scale, I have been thinking of the foundry crew since our visit, and I do hope that the pending cast was trouble-free and completely successful.”

Look out for notices of future visits to technical facilities and foundries organised by the Industry Committee.